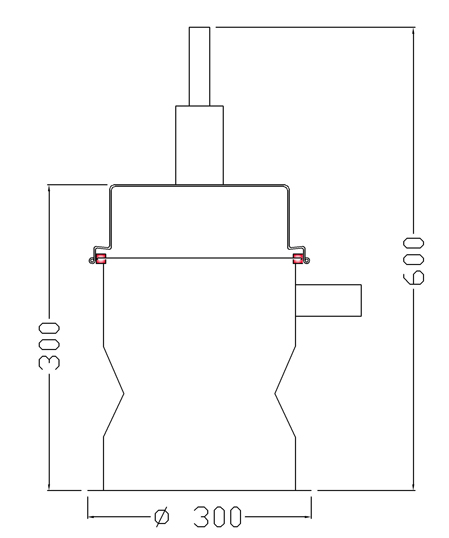

Rapid Fill, Compressed air operated - maintenance free vacuum loader for granules

Rapid Fill is compressed air operated, simple to operate and maintain granule loaders for plastic industry.

Why Rapid fill??

Rapid Fill is rugged, simple to operate timer based vacuum hopper loading system. It is low cost and practically zero maintenance and zero down time.

What are special features?

Special features are SS construction, zero maintenace, zero down time, simple operator friendly timer based operation, hopper on hopper design.

How to install hopper loader?

Just like any other hopper loader, it can be installed on hopper lid or lid of hopper drier.

Is there any over fill protection?

Rapid fill is provided with 2 filters. Internal SS mesh and outside non woven PP fabric. Because of construction, overfill is not possible. In case of reduced demand, hopper loader will keep on operating pump but conveying will not take place.

How much air is consumed?

Air consumption depends upon conveying rate per hour and type of granule used. However maximum cost of transfer of one kilogram of plastic granule is 3 paise ( about Rs. 30 per tonne / US $ 0.7 per tonne) at 3 meter conveying height. If loader is operated 100% cycle , i.e. 300 kgs / Hour, maximum air consumption is about 255 LPM (9 CFM)

What is shipping weight?

Shipping weight of complete system includes loader, timer controller, hose and suction wand is just 14 kilograms.

| Advantage | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||

| Applications | ||||||||||||||||

|

||||||||||||||||

For Product Demo, check our video page