Vortex Tube, Instant cooling, quick install, adjustable, compact refrigeration

What is a Vortex Tube?

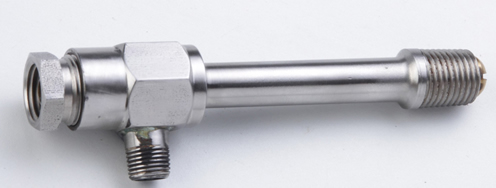

What is a General Imsubs Vortex Tube? The General Imsubs Vortex Tube is an effective, low cost solution to a wide variety of industrial spot cooling and process cooling needs. Compressed air is injected into the vortex tube, flows at a rate of up to 1,000,000 RPM towards the 'hot' end of the tube. Once this hot air reaches the end, a small amount is exhausted through a control valve. The rest of the air is forced backwards towards the other end and exits as 'cold' air. The Vortex Tube can decrease temperatures by ~115°F (46°C) and raise temperatures up by ~200°F (93°C) from the initial inlet air temperature. Vortex tubes are available in two sizes, Small and Medium depending upon compressed air consumption.

Which Vortex Tube will best suite my needs?

Our Vortex Tubes are available in 3 sizes (Small, Medium and Large). Each Vortex Tube is constructed of stainless steel. The wear resistance of stainless steel, as well as its resistance to corrosion and oxidation, assures that Vortex Tube will provide years of reliable, maintenance free-operation.

| Advantage of Vortex tube | ||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

||||||||||||||||||||

| Applications or Vortex Tube | ||||||||||||||||||||

|

||||||||||||||||||||

HOW IT WORKS: Vortex Tubes

- (A) Compressed air, normally 80 to 100 PSIG (5.5 - 6.9 BAR) enters the Vortex Tube through a standard BSP inlet and tangentially through a generator into the vortex spin chamber.

- (B) This air stream spinning at up to 1,000,000 RPM travels in one direction along the small (hot end) tube and then is forced back through the center of this outer vortex.

- (C) The brass control valve on the hot end allows for quick n' easy adjustment of the "cold fraction".

- (D) As the center column travels towards the opposite end, it gives off kinetic energy in the form of heat to the outside stream of air and exits the vortex tube as cold air.

PERFORMANCE: Performance mentioned here is at tube being set to maximum refrigeration. Air flow is at 7 bar (100 PSI) pressure.